In this tutorial, we will be converting a CUSTOMER ORDER into a WORK ORDER.

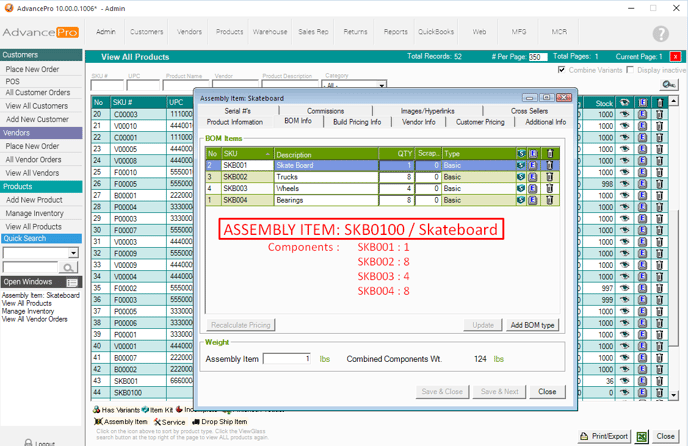

Assembly Item:

SKB0100 / "Skate board"

Components:

SKB001 : 1

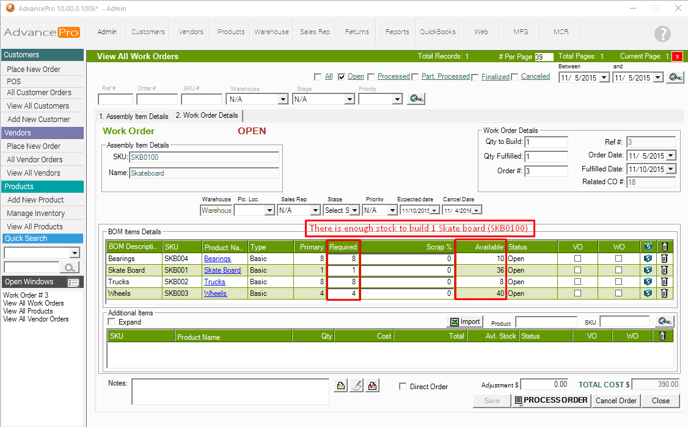

SKB002 : 8

SKB003 : 4

SKB004 : 8

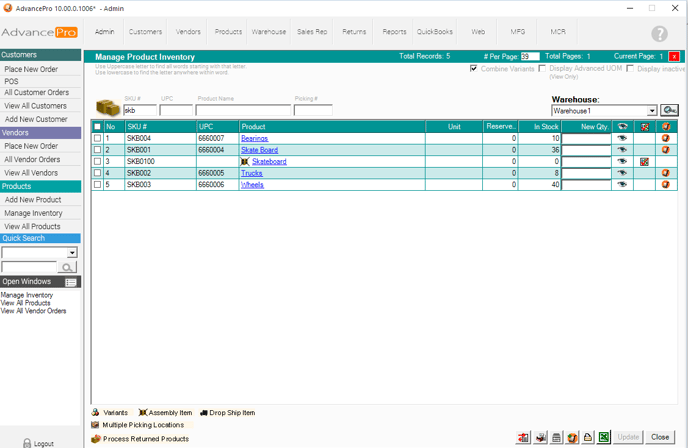

Current available materials:

SKB001 : 36 units

SKB002 : 8 units

SKB003 : 40 units

SKB004 : 10 units

:: This means we can build at MOST 1 Skate board only due to SKB002 having minimum materials available

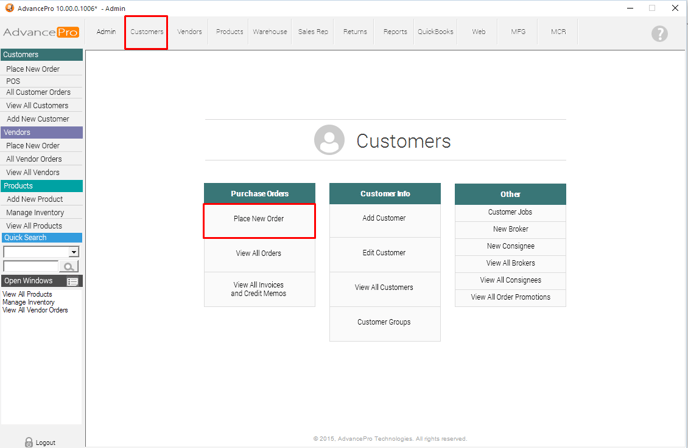

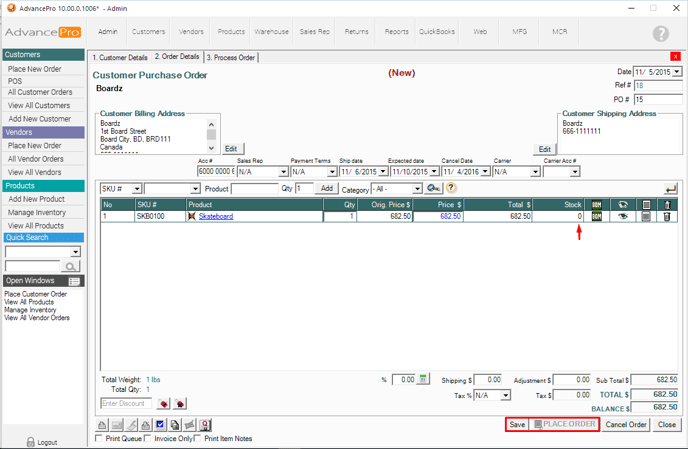

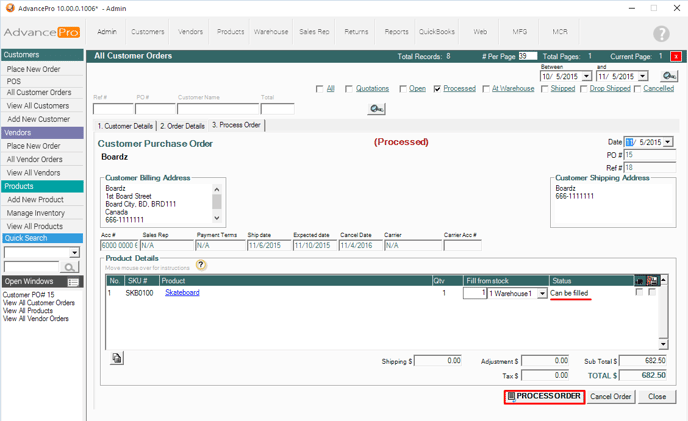

1. Place a Customer Order

2. Add the Assembly Item, "Skateboard [SKB0100]". Save and Place the Order

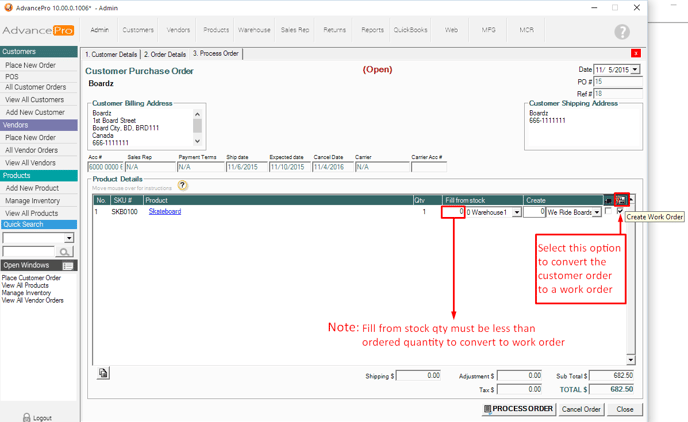

3. Check the box under CREATE WORK ORDER Column. The FILL FROM STOCK quantity must be LESS than the ORDERED quantity. The difference will be the number of items to be assembled in order to fulfill the order.

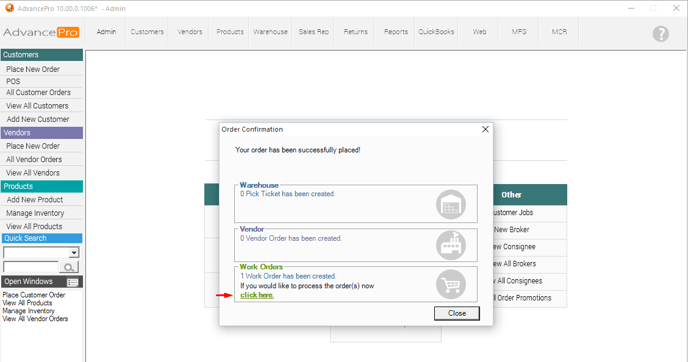

4. A Work Order will be created. See screenshot below.

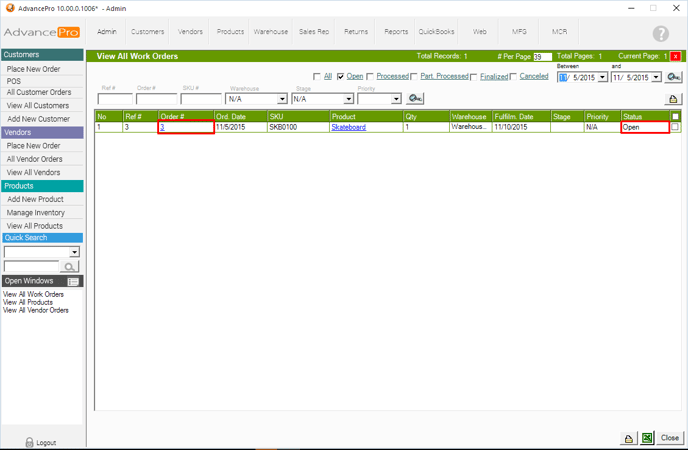

5. It will lead you to the OPEN work orders screen. You may also go to MFG >> View all Work Orders under Open status to view the order.

6. See if there are available stocks.

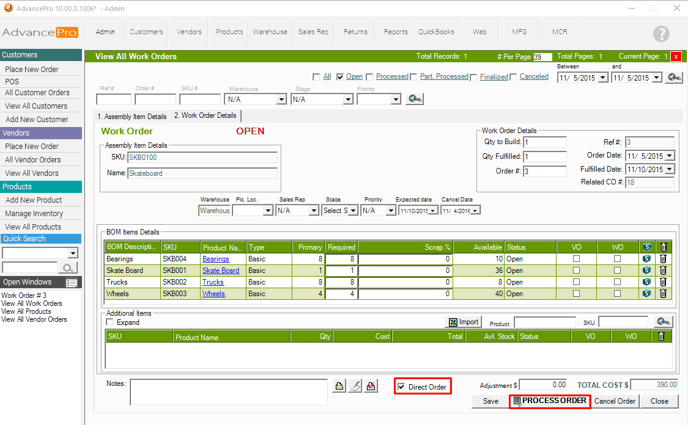

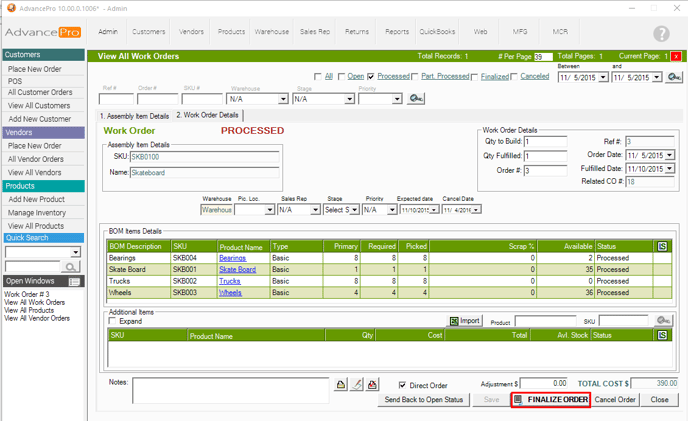

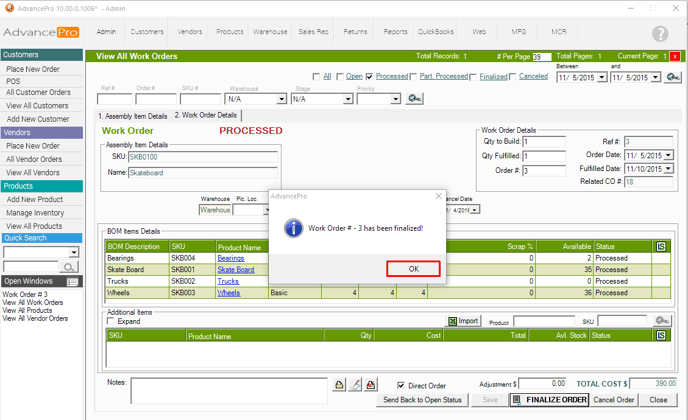

7. Process the order directly and FINALIZE.

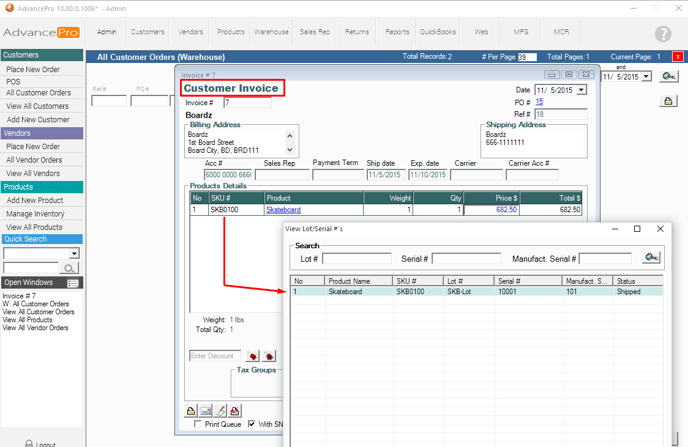

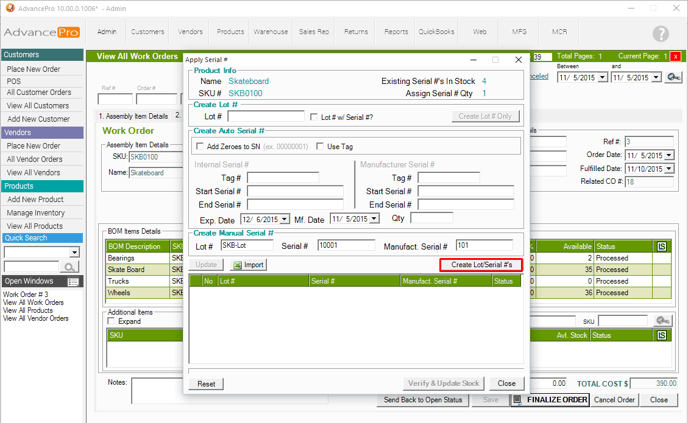

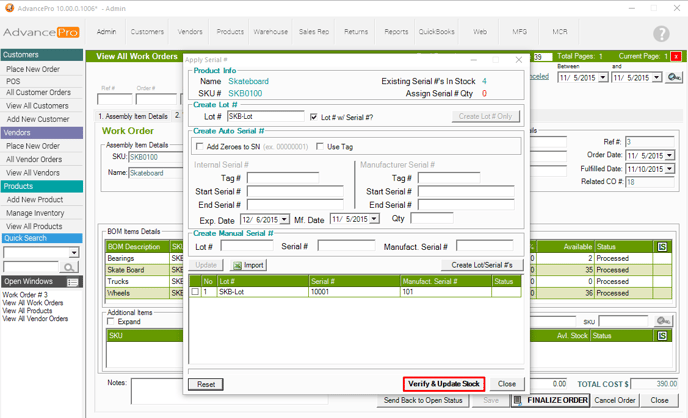

8. After FINALIZING, enter the LOT/SERIAL number of the assembly item.

**This is required for every assembly item (with or without the lot/serial module key enabled)

9. Verify and Update Stock based on the Lot/Serial Number

10. You customer order can now be filled.

Below is the CUSTOMER INVOICE with the Serial number of the assembly item.